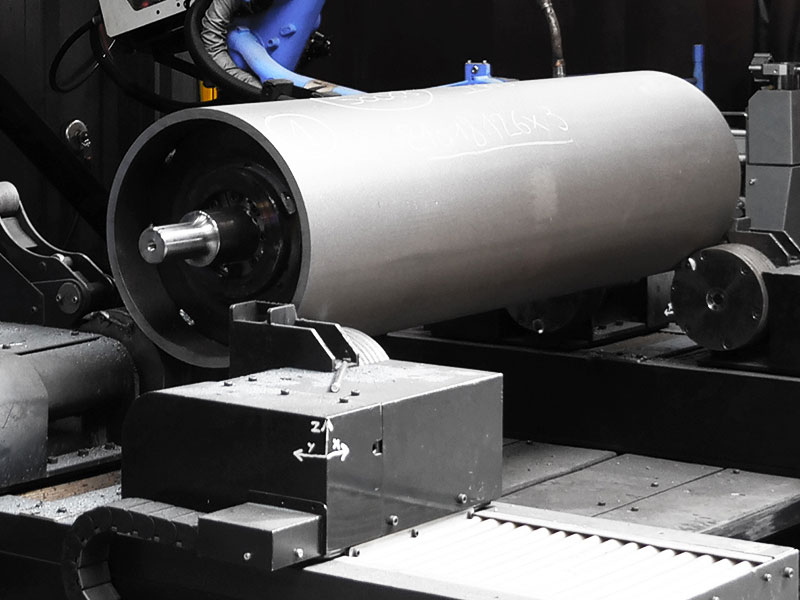

Manufacturer of handling drums for industrial equipment

ALTEMA has been manufacturing industrial drums, conveyor drums and handling drums for over 25 years.

These products are made to drawings or customer specifications.

ALTEMA’s experience, manufacturing processes and extensive machinery enable us to produce different types of drums and pulleys to meet every need, from the standard to the most specific.

Conveyor drums for all industries

- Quarries and mines

- Waste collection center

- Agri-food

- Automotive

- Fertilizers and chemicals

- Airport port

- Agriculture

- Steel industry

Quarries and mines

The mining industry is subdivided into a wide range of sectors, including the extraction of coal, metallic minerals, precious stones and non-metallic minerals. Raw materials are processed to meet a wide range of needs, particularly in the manufacturing, construction and infrastructure sectors. Whether at the time of extraction, or for the processing of these raw materials, numerous belt conveyors are required for these activities.

Waste collection center

Waste sorting methods vary according to the nature of the waste and the characteristics of the collection. To minimize the amount of waste going to landfill or incineration, ambitious new recycling and recovery targets have been set. ALTEMA conveyor drums can be found on sorting and processing systems for selective collection, household waste, industrial waste, composting, CSR processing, Machefer, sorting of CIW, WAS and rubble.

Agri-food

For 25 years, ALTEMA has been supplying conveyor belt drums for the processing of raw materials used in the food industry. This experience enables us to meet every requirement, from standard drums to squirrel-cage drums. ALTEMA conveyor drums are used on conveyors to transport cereals, sugar, salt, coffee and flour.

Automotive

In the automotive conveyor systems sector, conveyor belts have a wide variety of applications. For automotive parts and assemblies, conveyor belts are used to transport stamped parts at high speed and with maximum safety. The type of belt required depends on the material being conveyed.

Fertilizers and chemicals

ALTEMA supplies conveyor drums and pulleys for belt conveyors with loading hoppers or elevators in the fertilizer industry. From grasshopper conveyors to large conveyor systems for phosphate mining, ALTEMA can meet all the demands of these demanding sectors.

Port / Airport

ALTEMA supplies conveyor drums for handling bulk materials and general cargo. ALTEMA provides systems to simplify loading and unloading operations. The aim in these sectors is to keep vessel downtime to a minimum. The drums must be able to withstand the harsh climatic conditions associated with their seaside location (wind, salt, etc.).

Agriculture

ALTEMA is active in the agricultural sector, particularly in the handling of cereals on conveyor belts. ALTEMA conveyor drums are installed on belt conveyors, while bucket elevator pulleys are installed in silos, both used to transport raw materials in the agricultural sector.

Steel industry

The iron and steel industry produces pig iron and ships it to foundries where it is used to produce cast iron or steel. ALTEMA drum conveyors are installed on various systems: rolling mill plate conveyors, aluminum scrap belt conveyors, foundry raw parts conveyors.

History

- 2021: Acquisition of a welding robot

- 2020: Increase in the number of machines

- 2017: +1000m² workshop +200m² office space

- 2015: Acquisition of a new high-capacity NC lathe

- 2013: Increase in the number of machines and development of calculation software

- 2012: Increase in capacity and rubberizing types

- 2011: Acquisition of Solid Works (3D modeling)

- 2010: Increase in turning capacity: Ø1300

- 2008: Second extension (+1100m²)

- 2006: Increase in turning capacity: Ø800

- 2004: Installation of a massive stock of SNG plummer block housings

- 2002: Design of drum calculation software

- 2001: Creation of the bearing supply and assembly department

- 2000: Increase in turning capacity: Ø508

- 1998: Garnishing service launched

- 1997: First expansion (+700m²)

- 1995: Company set up in Mouilleron en Pareds (1200m²)

1995 Creation ofthe company

10,000 Drums per year

4,000m² Workshop area

Our tools

As a specialist in drums for bulk handling, ALTEMA designs and manufactures drums whose dimensions and characteristics cover the majority of today’s industrial needs. The company has all the resources required to meet the needs of its customers: conveyor manufacturers, design offices, distributors and maintenance companies in the materials handling sector:

-> Design software – Solid Works

-> Drum sizing software (dedicated software)

-> 4000m² workshop and production area

-> High-performance production tools

-> A wide range of machines covering a wide range of dimensions for both shafts and drums.

-> Latest and most suitable welding equipment

-> Areas and equipment dedicated to the laying of coatings

-> Large stock of raw materials, including tubes, axles and flanges, to meet your needs quickly.

-> Extensive range of plummer block housings held in stock. These bearings can be supplied alone or pre-assembled on the drums.

Our team

A dynamic and competent team of over 30 employees is at your disposal to advise you and offer you the service you expect. To offer you the best quality/price/time ratio, we have developed an optimized process and set up an efficient organization. This means developing our purchasing and stock management capabilities, and a rapid processing circuit to meet your express repair needs. Our loyal customers are major contractors in a variety of sectors (quarries, landfill sites, sorting centers).

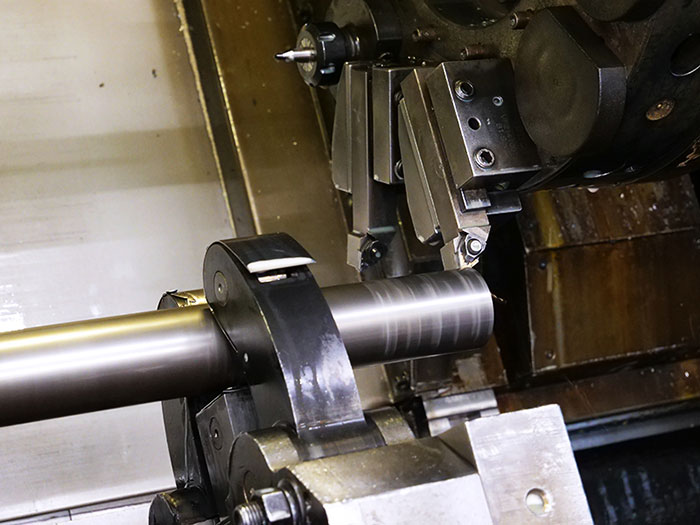

Large-scale machining

In general mechanics, machining refers to a set of techniques used to manufacture mechanical parts by removing material (steel, aluminum, stainless steel, etc.). In concrete terms, using a machine tool, material is removed in chips to give the raw part the desired shape and dimensions. The result is extremely precise.

A production tool adapted to the machining of large parts

ALTEMA has a substantial and versatile machine park. Thanks to our equipment, we can machine large axes, from 150mm up to 5000mm, and large diameters, up to 1300mm.

We have high-capacity CNC lathes with a large headstock, guaranteeing precise, high-quality machining to meet your requirements.

As a result, we can use our large CNC lathes to produce long parts, whether or not they are related to the conveyor belt drum sector. Based on your drawings, we then develop the optimum machining process to create parts that meet your expectations, however complex they may be.

Machining large axes is a highly specialized technique, requiring special know-how and specific tooling:

- Our experience in this field is synonymous with quality and reliability, even under the toughest conditions.

- Our fast response times enable us to provide our customers with answers and solutions tailored to their needs.

- Our experts are on hand to develop your project and create the right parts to suit your needs.

- We have a vast fleet of machines, offering a wide range of machining possibilities, to best meet your expectations.

- We can machine all your large parts, whether standard or custom-made.

- Our machine tools are numerically controlled, perfectly maintained and regularly calibrated, with quality and performance in mind.

Don’t wait any longer, contact ALTEMA to discuss your large machining projects!

The energy of a group

ALTEMA is part of FIDEIP industrial group.

With the FRENCH FAB label, it employs 360 people and currently comprises 12 companies specializing in mechanical engineering.

The FIDEIP Group promotes the fulfillment of men and women within organizations, through team diversity, employee commitment and talent development.

Group companies: Palamatic, Fidemeca, Jyga, Epsilon Tôlerie, LF Technologies, Mecaspin, Aivee, ID Wash, Plix, Robkub.