Expertise and advice for special drums & pulleys

Special drums and pulleys are produced on the basis of drawings supplied by customers. Drawings and technical requests are checked by departments within the design office to ensure compliance with standards and rules of the trade. From the outset, our sales team will be able to guide you towards the technical solution that guarantees the best technical and economic compromise, while respecting your deadline constraints.

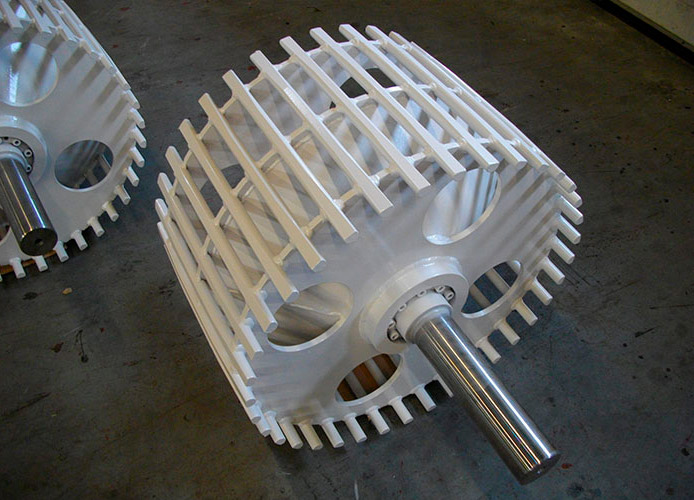

In addition, our “drum expertise” in the various sectors of activity enables us to advise you on the technical adaptations specific to the drum’s field of application. For each activity, there is a set of functional constraints to which ALTEMA provides appropriate technical solutions, thanks to the expertise it has acquired over many years working with its customers. The ALTEMA squirrel cage drum, for example, can be found in a wide range of sectors: quarrying, landfill sites, sorting centers, grain processing, food processing, iron and steel, automotive, port areas, mining…

ALTEMA’s experience enables us to meet all your requirements for special drums: mixing drums, squirrel-cage drums and rotary drums. These special drums benefit from over 25 years’ know-how in the manufacture of custom drums and pulleys.

Need for

Technical advice?

Call our drum experts

A range of drums for all sectors of activity

ALTEMA's experience enables us to meet both classic conveyor drum and handling drum requirements, as well as more specific needs in all sectors of activity: mining, quarrying, recycling, fertilizers, ports, food processing.

+10,000 Drums per year

+10 Business sectors

+500 satisfied customers

Do you already have the dimensions of your drum?

Send us your pre-filled request for a quick quotation using ALTEMA drawings.

SELF CLEANING PULLEYS

The self cleaning pulley is manufactured with bars welded to the side flanges instead of the tube as on a standard drum.

TAIL PULLEY

A tail pulley is positioned on a conveyor when it is transporting a material that will tend to stick to the conveyor belt.

IDLER DRUM

To meet specific needs on belt conveyors, ALTEMA can manufacture customized idler drums, also known as conveyor rollers.

CUSTOM DRUMS

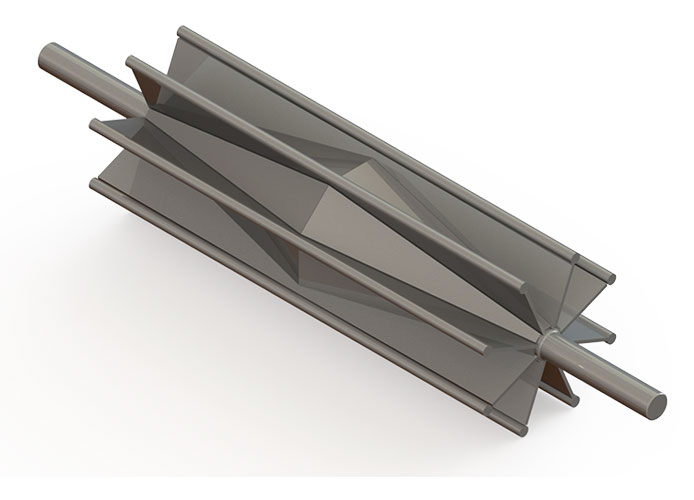

Custom drums are produced on the basis of drawings supplied by customers, and can also be modeled in the design office.

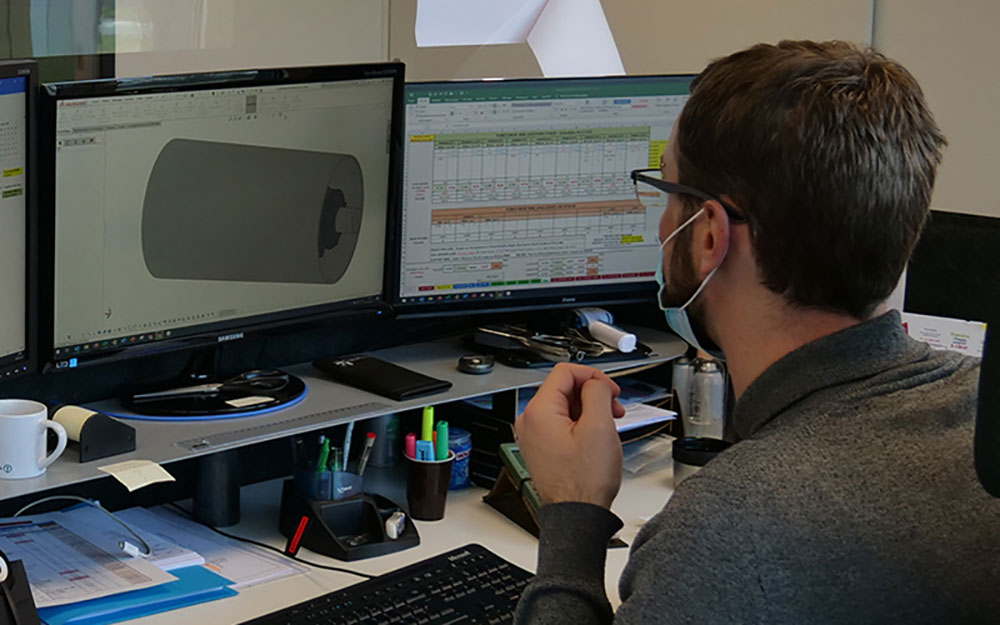

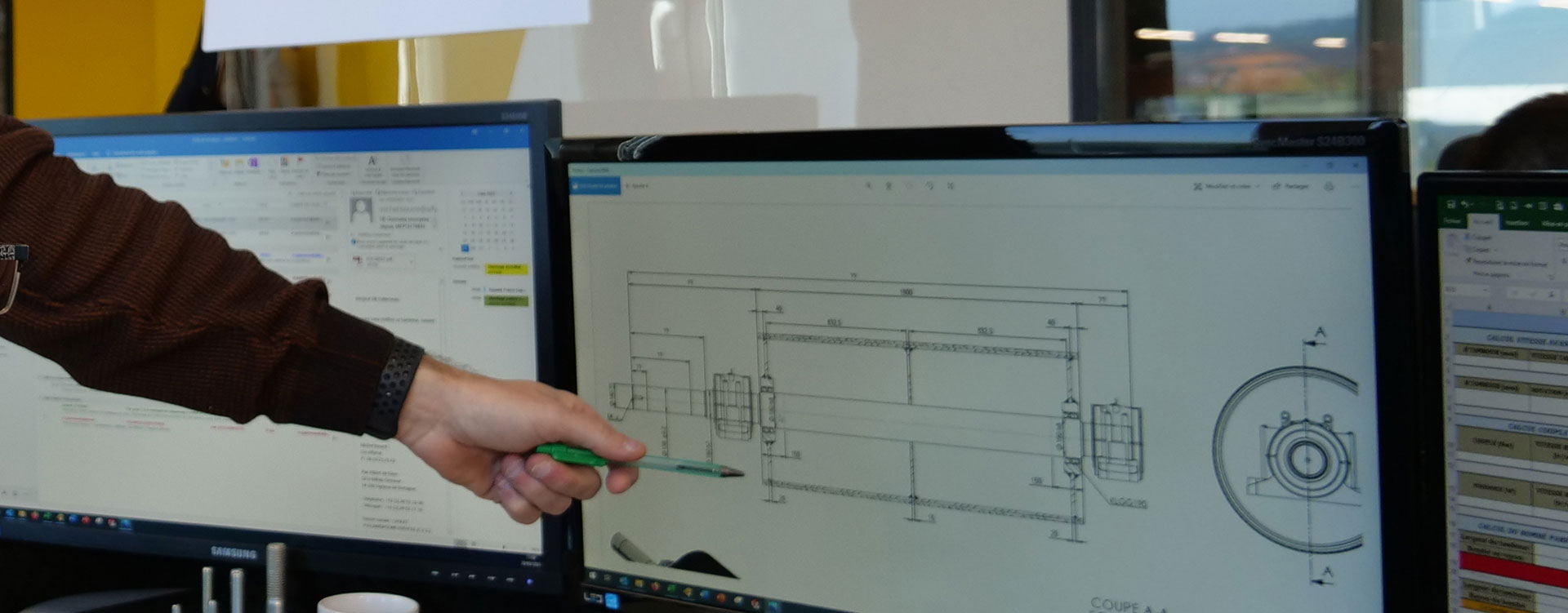

Specific drum design

ALTEMA’s design office can take charge of modeling your special drums using 3D CAD software (Solidworks). Thanks to the calculation software, he can also manage the sizing of your special drums (beater drum, squirrel cage drum, etc.) and help you optimize them: material, size, geometry, thickness and type of connection. For any specific request, please contact ALTEMA to discuss the best technical solutions.

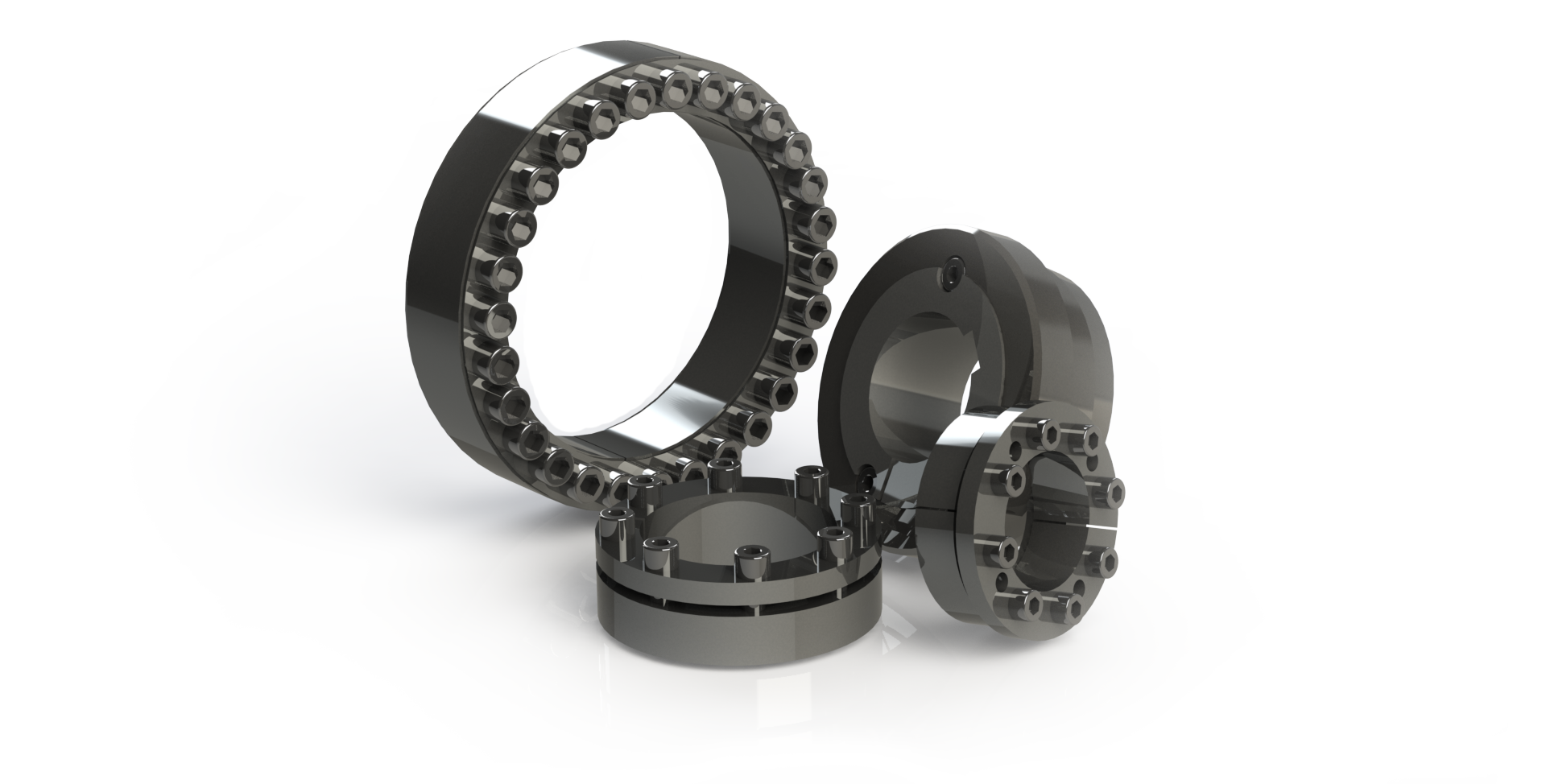

LINKING SYSTEMS for self cleaning pulley

ALTEMA offers various types of connections: Vecobloc hubs, flange bearings, shrink discs, etc.

CLAMPING RINGS

The radial deformation of the elements forming the head of the clamping rings ensures contact between the flanges and the shaft on a self cleaning pulley. Each part comes into contact with another at a specific angle, generating a pressure force and causing the discs to contract.

VECOBLOC HUBS

VECOBLOC removable hubs are the most practical system for securing the drum to its shaft without the need for special tools. ALTEMA offers a wide range of removable hubs to meet all requirements.

TECHNICAL SUPPORT IN DEFINING YOUR PRODUCTS

For over 25 years, ALTEMA has specialized in the construction of rotary drums for sectors such as mining and quarrying. The experience acquired over the years enables the company to offer personalized support. The aim is to provide our customers with the best technical and economic compromise, perfectly adapted to the destination of each customized conveyor drum. Dimensioning and technical choices, guided by this vast experience, ensure a long service life for the products manufactured by the company.

Altema services

RDM DIMENSIONING

ALTEMA's Engineering Department is able to dimension and verify conveyor drums and lifting pulleys using its RDM and 3D CAD calculation software.

Static and Dynamic Balancing

ALTEMA offers balancing solutions and services for high-speed conveyor drums, to keep them running at peak performance.

TECHNICAL SUPPORT

Depending on the application, the field of activity, the transported material and the climatic conditions, ALTEMA offers you specific solutions to optimise your products and improve your performance.